Our commitment to

product quality Our commitment to product quality

The reason COLOCOLO have been

loved for decades is our commitment

to product quality.

We produce high quality and

high performance through adhesives,

coating, finishing, and practical evaluation. The reason COLOCOLO have been loved for decades is our commitment to product quality.

We produce high quality and high performance through adhesives, coating,

finishing, and practical evaluation.

Formulating A whole new level of adhesive quality

The hotmelt adhesives used in COLOCOLO are created with a variety of usage environments in mind and without using any organic solvents which could potentially ignite. What is more, they are highly non-toxic to the human body.

At Nitoms, we utilize an experimental design method that uses applied statistics.

This results in efficient exploration and evaluation and allows us to select optimal blend patterns. In addition to processing them into actual tape and confirming their practical utility and suitability for machinery, we also verify them from a cost perspective, and only those blends that have cleared every assessment are used in products. At Nitoms, we utilize an experimental design method that uses applied statistics. This results in efficient exploration and evaluation and allows us to select optimal blend patterns. In addition to processing them into actual tape and confirming their practical utility and suitability for machinery, we also verify them from a cost perspective, and only those blends that have cleared every assessment are used in products.

Hotmelt adhesive

Including no organic solvents may be harmful to human body, and igniting less carbon dioxide which is environmentally harmful through production. Human- and earth-friendly production are also a commitment of Nitoms.

Coating Coating technology that

gives rise to variation Coating technology that gives rise to variation

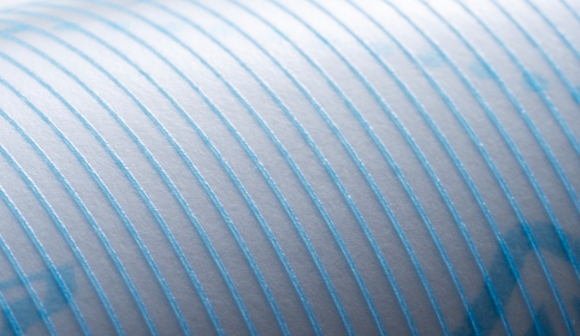

COLOCOLO comes in a variety of coating patterns, each suited to a particular purpose. In order to produce the coating patterns that comes in various designs, such as solid, striped, dotted, and double adhesive, Nitoms has original facility that takes the adhesives and machine suitability into account.

Preventing mishaps such as adhesive sticking to the floor during cleaning is one important factor for adhesive coating technology that controls the adhesion properties between the rear surface of the tape and the adhesive itself.

Double Adhesive

The “double adhesive,” consists of a weak adhesive layer applied on top of a strong adhesive layer, is applied on MULTI-FLOOR CLEANER Series. This double layered adhesive makes multi-purpose use possible.

Spike Dot Adhesive

The “spike dot adhesive,” which picks up hairs and dusts on carpets and rugs, is applied on HIGH GRADE Series. The stripes and dots pick up small particles from deep within carpets.

Finishing technology Advanced finishing technology

that determines usability Advanced finishing technology that determines usability

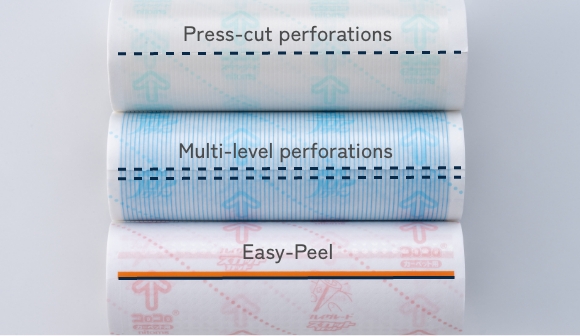

To allow for continued comfort during use, COLOCOLO pays particular attention to the perforations in its finishing technology. Different technologies such as “Multi-level perforations,” “Press-cut perforations,” “Easy-Peel” are used depending on thickness of base material and adhesive.

Another example of COLOCOLO’s advanced finishing technology is that it provides the tape with the optimal amount of flexibility to prevent dirt and dust attached to the surface from falling off during tearing.

Perforation technology

“Multi-level perforations” offset the positions of the perforations bit by bit, keeping tearing easy and suppressing rattling during use; “press-cut perforations” concentrate perforations of unique widths in the same location to allow for smooth movement; etc. Different technology is used depending on the product types.

Easy-Peel

The “Easy-Peel,” with its distinct orange color has excellent visibility and allows for very clean tears. The orange line is made with a film substrate with high strength per unit area. Even when long strands of hair and other such debris are rolled up, the tape does not tear lengthwise and waste a new sheet.

Practical evaluation Our company’s strict evaluation

criteria for securing reliability Our company’s strict evaluation criteria for securing reliability

For COLOCOLO, we conduct various types of practicality tests at the new product development and existing product improvement stages. As an industrial product, we naturally conduct tests based on JIS (Japanese Industrial Standards Committee) specifications, but the tests established by JIS are not sufficient for carefully evaluating practicality for COLOCOLO’s many usage scenarios. These strict evaluation criteria are the pride of the trailblazing pioneer that is COLOCOLO.

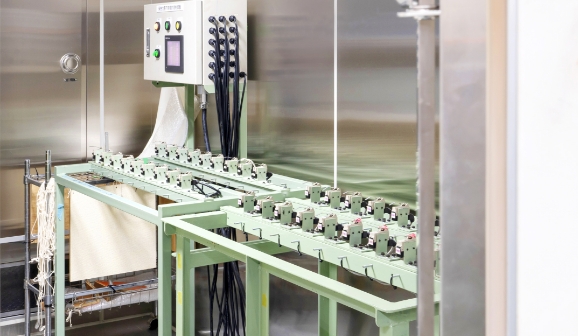

Dust picking ability test

We use original testing methods for various usage situations. We measure and evaluate the remaining adhesive strength and other factors during actual usage scenarios.

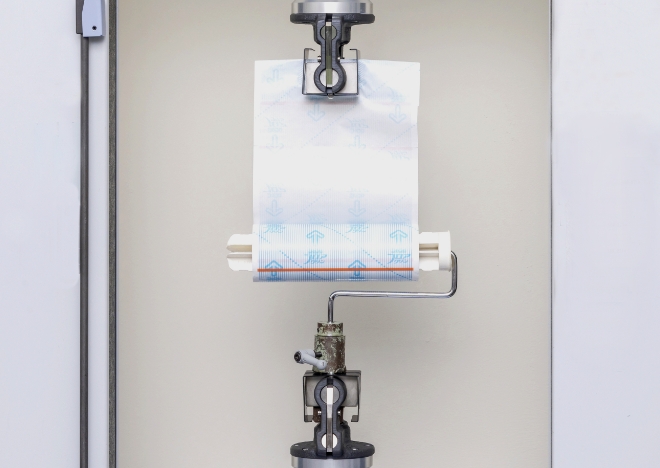

Preservation stability test

Product quality must be maintained regardless of large seasonal heat or humidity differences. In a constant-temperature and constant-humidity chamber, it is possible to perform tests that anticipate the temperature and humidity of the seasons. To prevent deterioration in quality due to heat, light, and so on, COLOCOLO adhesives include age resisters in their blends. We evaluate long-term preservation stability using a durability testing machine.